Modern mushroom cultivation requires much more than just suitable compost and high-quality spores. Without reliable mushroom farm equipment, it is impossible to maintain optimal production conditions, meet hygiene requirements, or ensure efficient harvesting. Today’s farms depend on a combination of mechanical engineering, automation and environmental control. Choosing the right equipment directly affects yield quality, labour costs and the sustainability of operations.

What defines high-quality mushroom farm equipment?

When evaluating equipment for your mushroom farm, the primary criteria should always be durability, precision and compliance with hygiene standards. For instance, picking lorries must be made from corrosion-resistant materials like stainless steel or aluminium, especially in high-humidity environments. Similarly, watering jets require precision nozzles that allow for uniform distribution of water without waterlogging or waste.

Modern mushroom farms also rely on automated winching systems to move shelves and nets. Here, reliability and automation compatibility are essential. Inaccurate movements or delays in operation can affect harvesting times and compromise the condition of the crop. That’s why equipment available from specialised manufacturers is typically tailored to support seamless workflow and integration with other systems.

Investing in the right mushroom farm equipment in Poland and across Europe

In countries like Poland, where mushroom cultivation is one of the key agricultural sectors, choosing the right equipment is especially important. Polish farms are known for their high production standards and exports to many European markets. This means local growers often work with high-capacity systems that need to be both efficient and compliant with European Union regulations regarding materials safety and environmental impact.

One notable aspect is the importance of energy efficiency. With rising energy prices and tightening emission standards, choosing systems with low power consumption and high thermal insulation has become essential. Equipment such as heat recovery units or LED lighting systems for harvesting areas not only reduce production costs but also help farms meet sustainability targets.

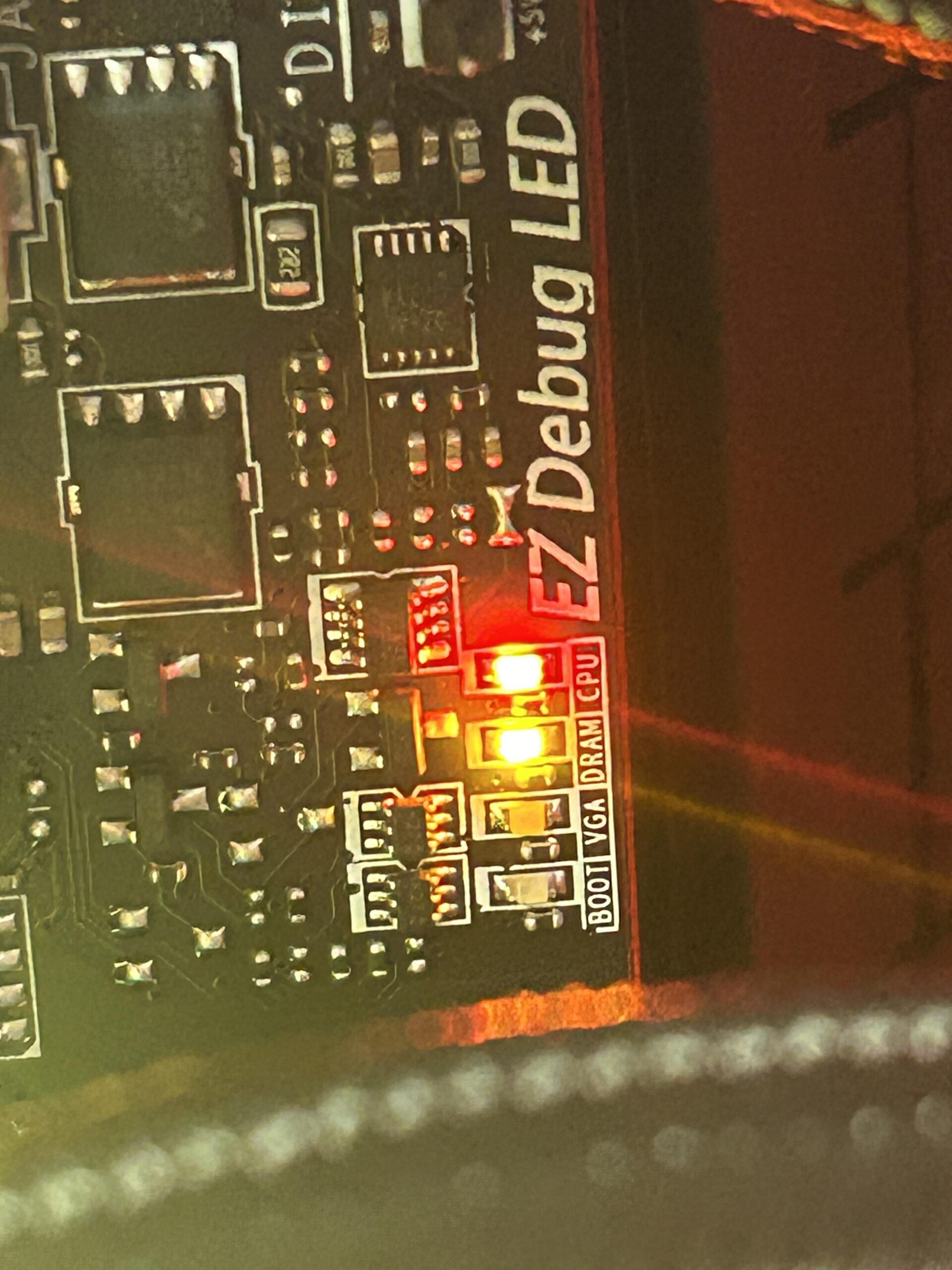

Another critical factor is ease of maintenance. Systems that are difficult to clean or service increase downtime and risk of contamination. That’s why leading manufacturers prioritise ergonomic design and tool-free maintenance features. Farms using this kind of equipment can ensure uninterrupted production and minimise biosecurity risks.

Flexibility and long-term adaptability of farm systems

When choosing mushroom farming equipment, it’s important to consider flexibility and the ability to grow over time – especially for farms looking to expand or respond to changing market needs. Equipment with modular design, adjustable features, and support for new technologies is usually much more useful than fixed, one-size-fits-all systems.

Flexible equipment makes it significantly easier for farmers to increase production, try new mushroom varieties, or improve processes without having to replace everything. For example, control panels that allow software updates or shelving that fits different tray sizes are smart, long-term investments.

Because farming conditions and regulations can change quickly, having equipment that can adapt helps farms stay efficient, avoid costly upgrades, and as a result build a stronger, more sustainable business.